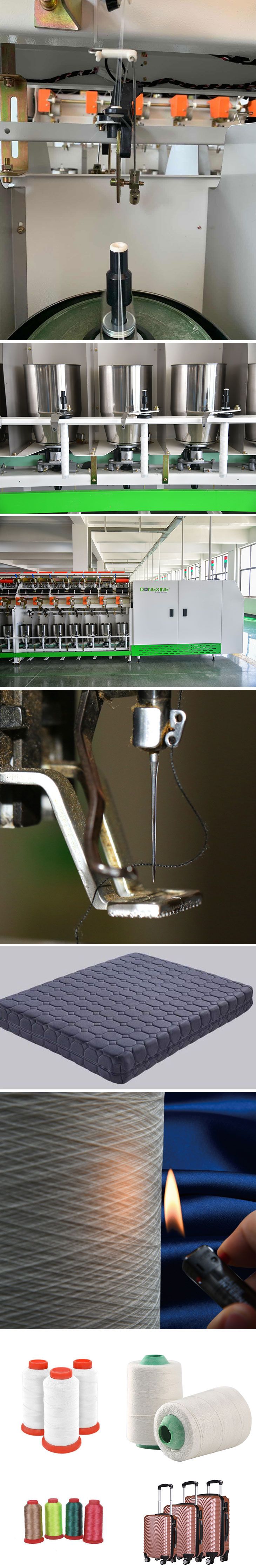

Secondary twisting machine

Product categories:TwistingThe DONGXING DX321F Twisting Machines are the answer to increasing energy costs, offering tire cord manufacturers enormous, even revolutionary production cost savings together with further quality improvement.

product description

The DONGXING DX321F

The DONGXING DX321F Twisting Machines are the answer to increasing energy costs, offering tire cord manufacturers enormous, even revolutionary production cost savings together with further quality improvement.

Power consumption reduced by up to 50 %

Heat load reduced by up to 50 %

Significantly reduced noise level

Up to 50 % fewer yarn breaks

Maximum economic efficiency and quality thanks to state-of-the-art technology

Two-for-one twisting machines for industrial yarns

Designed for new challenges in the two-for-one twisting of industrial yarns

This is the world of technical yarns. They are used in mechanical engineering, in aviation and space travel, in medical technology, in the automobile industry, in the building industry and many other products for today and tomorrow.

High-quality end products require high-quality production means. With the two-for-one twisting machines for industrial yarns, DONGXING customers benefit from technological leadership and top quality machine construction together with a long-standing partnership of mutual trust.

| Spindle gauge | 290mm |

| Spindles per section | 12 |

| Standard sections per set | 12 |

| Standard spindles per set | 144 |

| Spindle type | 166/230 |

| Yarn pot type | 166/230 |

| Operation method | pneumatic / manual |

| Processing material | 400D-1260D filament |

| Spindle running speed | 2000-8000rpm |

| Twists range | 200-1500TPM |

| Feed-in bobbin | straight bobbin |

| Feed-in yarn package weight | ≤4kg |

| Winding up bobbin | 230mm/straight bobbin |

| Winding up package weight | 4kg |

| Winding up yarn speed | ≤80m/min |

| Yarn shaping control | servo control system |

| Spindle driven method | Long belt |

| Twist direction | s/z |

| Tension control | steel ball, flyer |

| Power configuration | 2pcs of 380V/11kw/15kw motors |

| Input power and capacity | Three-phase 380V/50Hz/80A |

| Operataion control | Touch Screen |

| Dimension | headstock+tailstock: 3m, machine body: 2.04M*12 sections, width: 1.5M, height: 1.5M. |

Machine Features:

1.DX321F adoptes servo system, inverter, PLC, touch screen and microcomputer control synchronous system.

2.Suits for filament yarn TFO twisting and reverse TFO twisting for DX268V winding up yarn, its finished yarn package weight can reach to 4kg big each, and twisted yarn no knotting and no no oil-stained yarn, provides high quality soft cones directly to cone dyeing.

3.Energy saving design, adoptes two main motors to drive, which not only solved belt uneven tension problem, also declined energy consumption.

4.DX321F adoptes servo system, compared to traditonal gearbox system, servo system has simple structure, no pollution, less noise, easy maintenance, various shaping technology, and better yarn shaping and machine running stabilization.

5.All the high quality parts composed the excellent yarn path, minimized yarn damage duiring its processing and much better suitable for high quailty yarn production request.

6.Based on features of filament yarn, we did many modifications to DX321F, and provide low energy consumption, less manpower requirement and exclusive machinery to replace traditional compound twisting machine at certain level.

7.Can be using as secondery TFO in two times twisting (S and Z) process.